Rocker Panel Repairs

Here is the car in 2002 with the hidden rust up under the front of the rear quarter and all through the rocker panels -- hidden by the bolt-on outermost rocker panel.

This feature shows the rocker panel rust repair done to an 911SC during the winter and spring of 2006. Body work, even replacing welded parts with new, is more of an art than a science. Parts don't fit perfectly and have to be made to fit, and there aren't good manuals for even a relatively simple job like replacing the rocker panels.

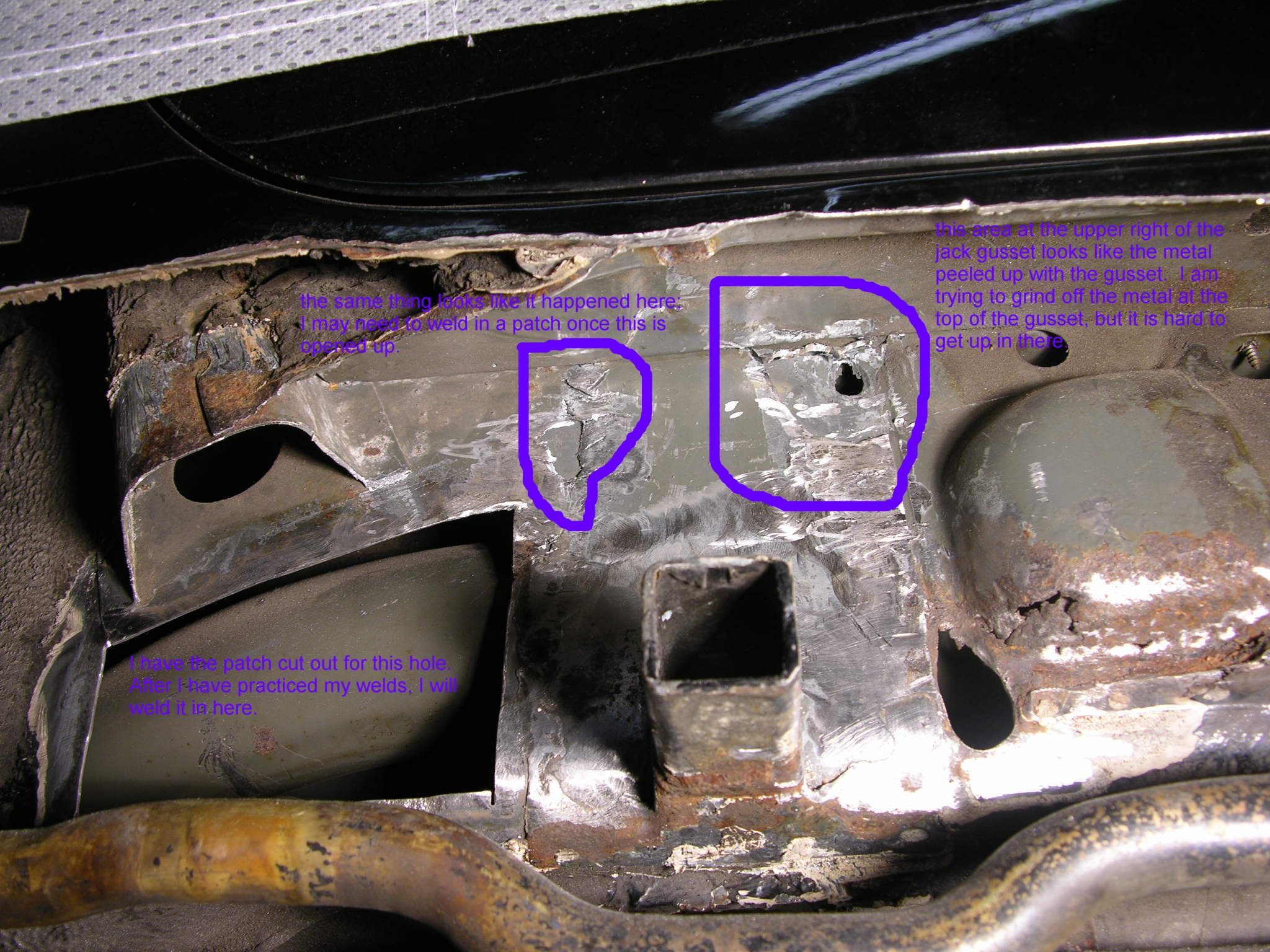

This is what the inner rocker panel looked like when the outer bolt-on panel and the welded-on door jamb panel were removed.